Discover the latest upgrade to the Dipping Coater by Zeus Techno, designed for enhanced nail coating efficiency and precision. The improved system features an automated brush mechanism, splash protection, and eco-friendly coatings, ensuring a cleaner and safer operation. With added drying capabilities and innovative design, it sets a new standard for superior performance in nail coating processes.

We are pleased to announce a significant upgrade to our Dipping Coater, aimed at improving both its performance and efficiency. The recently enhanced CN-90 or MC-5 dip coating system introduces several key improvements:

We are pleased to announce a significant upgrade to our Dipping Coater, aimed at improving both its performance and efficiency. The recently enhanced CN-90 or MC-5 dip coating system introduces several key improvements:

1. Enhanced Indexing System: The previous 6-index system has been upgraded to an 8-index system. This new design allows for a more efficient coating and drying process. The extended rotation time enables the integration of a hot air blower, facilitating faster and more thorough drying of coated nails.

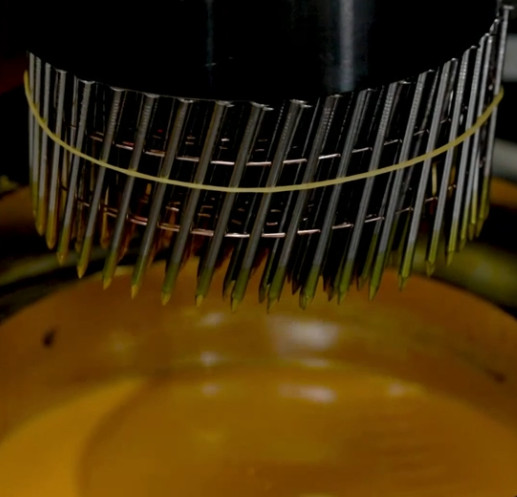

2. Automated Brush Mechanism: The upgraded Dipping Coater now features an automatic brush system that wipes off excess coating solution. Unlike the stationary brush in earlier models, the new mechanism moves up and down or rotates automatically, powered by a cylinder. This ensures a precise application and eliminates unwanted dripping.

3. Improved Splash Protection: A newly added cover effectively seals the critical areas of the coating system, preventing splashing of the coating solution. This not only enhances safety but also reduces the need for frequent maintenance and cleaning.

Existing customers operating Zeus Techno collators such as CN-90 or MC-5 can benefit from the upgraded Dipping Coater by having it installed on their current equipment. This ensures compatibility and allows customers to take full advantage of the new features without needing to replace their entire system.

If you are interested in upgrading your existing Dipping Coater, please contact your sales representative or the Zeus headquarters directly for a price quote.

The Dipping Coater has long been an integral part of our collators, which produce nail coils for pneumatic tools. It was developed in response to customer needs for lubricating nails to ensure smoother penetration into wood and to enhance the durability of the joint. Lubrication is particularly crucial for longer nails, where pneumatic tools must exert maximum force to drive the nails deeply enough, eliminating the need for manual hammering.

Our upgraded Dipping Coater is designed with precise height adjustment for applying the coating to the nail shank, ensuring consistent results tailored to customer requirements.

For optimal coating quality, immersion remains the most effective method. This process involves dipping the nails into the coating solution, followed by automated removal of excess coating with a brush to ensure even application. This modern approach replaces outdated roller-based methods, which were not only less precise but also caused contamination of the machinery due to splashing during operation.

We have also transitioned to using environmentally friendly, water-based coatings, replacing hazardous substances such as acetone (flammable and explosive) and dichloromethane (toxic to humans and the environment). The switch to water-based coatings presented a new challenge due to longer drying times. Our upgraded Dipping Coater addresses this issue with a preheating tunnel, where nails are warmed to accelerate the drying process. Combined with hot air blowing and the 8-index rotation system, the Dipping Coater ensures a clean working environment without splatters, even in high-speed production settings.

The latest upgrades to the Dipping Coater reaffirm our dedication to innovation and our ongoing effort to meet customer demands with solutions that are both efficient and sustainable.

For more details, visit

CN-90

or

MC-5

model at our website.