The CN-90L Wire Welding Collator is our response to customization requests from our customers. Now we are proud to introduce the new CN-90L, an improved version of the CN-90 with a reverse machine direction for added differentiation. Moving forward, the CN-90 will be referred to as CN-90R. When used together, the CN-90R and CN-90L can be positioned to face each other, allowing a single operator to efficiently manage both machines simultaneously.

The development of the CN-90 into the CN-90L creates a unique opportunity for collator placement that not only conserves valuable space in the production hall but also offers new options for labor savings and increased production efficiency. When used together, the CN-90R and CN-90L can be positioned to face each other, allowing a single operator to efficiently manage both machines simultaneously. This design significantly reduces the operator's movement range, thereby enhancing work speed and overall efficiency.

In addition to increasing user convenience, the CN-90L highlights our exceptional customization capabilities. We tailor the CN-90R and CN-90L to meet each customer’s specific operational needs, providing a truly personalized solution. We look forward to the positive impact the CN-90L will have on our customers' operational efficiency!

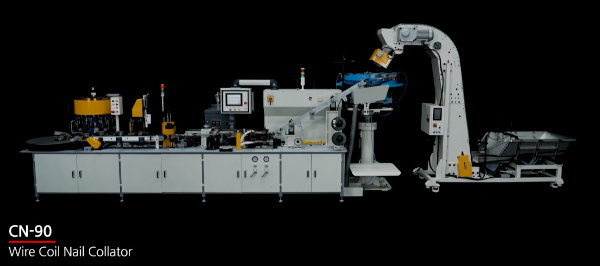

The Wire Welding Collator CN-90 is one of ZEUS's longest-produced machines and is thus also the most widely used among customers. It operates on all continents, including Africa, Europe, and the Americas. Frequently, it is deployed in facilities where multiple CN-90 collators run simultaneously, with as many as ten machines working in parallel. Customers will certainly appreciate the potential to save both workspace and labor.

Furthermore, a significant efficiency boost is achieved by the subsequent addition of an autopacker robot, which places completed nail coils into boxes. Previously, using individual CN-90 collators required either manual labor or a dedicated robot for each machine, making this new tandem setup highly advantageous for streamlined operations.